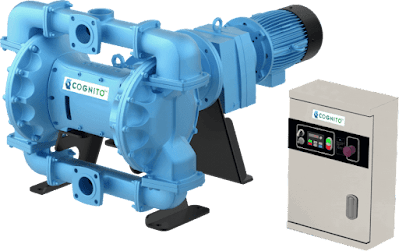

How IDEX Cognito EODD pump helped a market leader in sanitaryware production derive better results

In the world of EODD pumps, IDEX India's Cognito EODD Pumps have made a name for themselves. With their robust design, low MTTR and high MTBF, electro-mechanical operations, and max suction lift of 85m in wet conditions and 5.5 m in dry conditions, they offer operators world-class performance. With Congnito EODD pumps, operators can monitor the performance remotely. Not just that, but designed for better performance and longer life, these EODD pumps offer customers high value for money.

Cognito EODD pumps have been designed while taking

valuable feedback from IDEX's clients. This ensured the development of an EODD

pump that was built to be compatible with intense applications. While designing

the pump, two essential things were in focus: the production efficiency of the

users and cost efficiency, both in terms of the cost of ownership and the

lifecycle cost.

So where are Cognito EODD pumps used? The applications include slip recirculation, mixing tank transfer, slip casting house, glazing, slurry transfer, fliter press feeding, sludge transfer, and loading and unloading of the equilization tank. They are also used in industries where operators need to transfer raw materials, emulsions, and solvents.

One of the highlights of Cognito EODD pumps is that they have a larger diameter with shorter stroke lengths. This results in a longer life of the diaphragm because of less resistance. Owing to the specially designed seats and stopper cage arrangement, the manifolds and seats last longer as well.

All operators of Cognito EODD pumps are provided with Cognito Smart Insights, a web-based portal that allows you to monitor the performance of the pumps from anywhere. With this service, operators can get real-time updates on the pumps, including preventative maintenance alerts. The operators can also monitor the health of the applications and the pumps with just a few clicks. In the event of any abnormal pressures or leaks, the web application immediately notifies the operators. This service also offers actionable insights and reports that help operators optimise their processes in the long run.

While using various kinds of pumps, most operators constantly face the issue of maintaining the line pressure at a set value. This results in energy waste, higher operational costs, and wear and tear on critical equipment.

Here is an excellent example of how IDEX Cognito EODD pumps solved a major problem faced by a client in the sanitaryware industry.

The client mentioned above had a slip house on the ground floor of their production house and a casting house on the second floor. They needed an efficient way to move fluids from the ground floor to the second floor. But they were using a screw pump to move the fluids from the ground floor to the second floor, and this led to a constant pressure spike where there was no way they could control the speed of the screw pump. This problem did not just result in high energy consumption because of the frequent pressure spikes but also damage to pump parts such as rotors or stators.

So, how did IDEX's Cognito EODD pumps address this issue? Well, the EODD pumps were paired with a PID controller to rebuild the system logic in such a way that it automated the speed control with which the fluid was moved while maintaining the desired pressure in the system. Whenever the fluid was moved or recirculated at high pressure, the automated system reduced the speed of movement. At the same time, the pump attained a speed of 40 Hz every time the casting process was set off. With the automated system in place, the smart pump was tripped at the end of the batch and restarted after regular intervals to minimise the effect of torque at the end of the batch. The result was a significant amount of savings in terms of power consumption and an improved lifecycle of the machines and pumps in use.

The efficiency of the Cognito EODD pumps can be attributed to the fact that they were designed in collaboration with IDEX customers. The partnership made the whole design process more customer-centric, with the end user in mind.

The digital controls further allow the operators to adjust things such as the flow rate, pressure, and cycle time. At the same time, digital controls offer efficient remote monitoring, giving the operators peace of mind as they are constantly in the know regarding daily operations.

Modern technology has also enhanced the way a pump is

operated. For example, modern pumps, such as Cognito EODD pumps, use sensors to

detect and respond to pressure or flow changes. This results in high

productivity because no appliances need to be shut down if there is no one to

manually adjust any variable in real time. The appliances can work non-stop

because the pumps are, in a way, running themselves. That is the beauty of

modern technology!

Comments

Post a Comment